- Homem

- Automation Workbench

Automation Workbench

Automation Workbench

FEATURES

The platform includes nine industrial PLCs (Allen-Bradley/Siemens). It is an open platform to explore a wide range of PLC applications. The system provides extremely easy and student-friendly software to develop different programs. PLCs can be interfaced with different application modules.

TECHNICAL SPECIFICATIONS

PLC1 has 14 digital inputs and 10 digital outputs with USB communication facility. PLC2 has 16 digital inputs and 16 digital outputs with Ethernet communication facility. PLC3 has 8 digital inputs and 6 digital outputs (relay) with USB communication facility. PLC4 has 24 digital inputs and 16 digital outputs (relay) with USB communication facility. PLC5 has 6 digital inputs, 4 digital outputs, 2 analog inputs, and 1 analog output with Ethernet communication facility. PLC6 has 18 digital inputs and 12 digital outputs (relay) with USB communication facility. PLC7 has 8 digital inputs, 7 digital outputs (relay), 4 analog inputs, and 1 analog output with Ethernet communication facility. PLC8 has 8 digital inputs, 2 analog inputs, 2 analog outputs, and 4 digital outputs with Ethernet communication facility. PLC9 has 8 digital inputs and 6 digital outputs (relay) with USB communication facility. The switches module includes 4 push button switches and 4 push on/push off switches with PLC connection via 4 mm sockets. The sensor module includes 2 proximity sensors, 2 photo sensors, and 2 RTDs with PLC connection via 4 mm sockets. The relay control module includes 4 double pole/through relays with operating voltage of 24V DC and PLC connection via 4 mm sockets. The indicators module includes 4 visual indicators operating at 220V AC, 2 audio indicators operating at +5V/+12V DC, with PLC connection via 4 mm sockets. The seven-segment display application module and the AC induction motor control application module are both connected to the PLC via 4 mm sockets.

Tell us what are you "Looking for?"

Related Product

Related Product

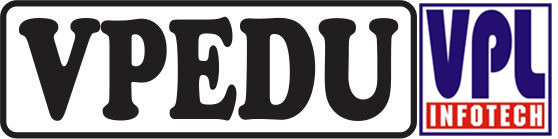

PLC & HMI Training System (Allenbradley/Siemens)

SPECIFICATIONS 1. PLC Unit – 1 No. At least 16 digital inputs, each connected with toggle switch and 4 mm sockets. At least 16 digital outputs, each connected with 4 mm sockets. At least 4 analog inputs on 4 mm safety sockets with options to switch to simulate via potentiometer. At least 2 analog outputs on 4 mm safety sockets. Inbuilt 24V DC power supply unit. This PLC unit is compatible with the above electropneumatics kit and also with the modular production system mentioned below. Preference: Reputed make. Mounting arrangement to fix with electrical mounting frame and able to use as a tabletop. 2. PLC Programming Software 1 user: 1 No. (perpetual). 3. Touchpanel – 1 No. Size: At least 7 inches. Touch and button functionality. It has an Ethernet switch to connect with the above PLC. Mounting arrangement to fix with electrical mounting frame and able to use as a tabletop. 4. Ethernet Cable, 2M – 2 Nos.

IIOT Enabled PLC-based Sorting Process Control Application Training System

FEATURES The PLC (Allen-Bradley/Siemens) system is equipped with 8 digital inputs, 6 digital outputs, 2 analog inputs, and 1 analog output, providing the necessary I/O capabilities for various industrial automation tasks. It also features Ethernet communication support, enabling seamless integration into industrial networks for remote monitoring, control, and diagnostics. The system comes with licensed PLC programming software, allowing users to program the PLC using standard languages such as ladder logic or structured text. Real-world components like pneumatic solenoid valves and pneumatic cylinders with reed switches, a small air compressor, conveyor belt with DC brushless motor and its driver, inductive and capacitive proximity sensors, toggle switches, selector switches, visual and audio indicators, DC motors, relays, contactors, and voltage displays offer students hands-on, practical experience with equipment they might encounter in the field. The system also allows sorting process monitoring and control from anywhere using mobile devices and applications. TECHNICAL SPECIFICATIONS The PLC has 8 digital inputs, 6 digital outputs, 2 analog inputs with 10-bit resolution, and 1 analog output with Ethernet communication facility. The system includes 8 toggle switches, 5 push-to-ON switches, 1 proximity sensor, 1 selector switch, 4 visual indicators, 1 audio indicator, 1 DC motor, 1 relay card containing 2 relays, 1 contactor, 2 pneumatic solenoid valves, 2 pneumatic double-acting cylinders with magnetic reed switches, a Nema17 planetary geared BLDC motor (14 Kg cm, 290 RPM) with industrial brushless DC motor driver (BLDC, 250W) with RS485 Modbus, a small air compressor, and 1 IIOT device. EXPERIMENTS Program operation of NO (normally open) and NC (normally closed) instructions, types of logic gates, set and reset bit, types of timers (TON, TOFF, TONR), types of counters (CTU, CTD, CTUD), types of compare instruction, types of math functions, MOV inst..

IIOT Enabled PLC based Elevator Control Application Training System

FEATURES The PLC (Allen-Bradley/Siemens) system is equipped with 20 digital inputs, 12 digital outputs, 4 analog inputs, and 2 analog outputs, providing the necessary I/O capabilities for various industrial automation tasks. It also features Ethernet communication support, enabling seamless integration into industrial networks for remote monitoring, control, and diagnostics. The system comes with licensed PLC programming software, allowing users to program the PLC using standard languages such as ladder logic or structured text. It includes a 4-floor model designed for training purposes to observe the PLC and electromechanical applications together. The system is designed in a transparent structure to examine the mechanical and electronic systems. Real-world components like DC motors, limit switches, proximity sensors, toggle switches, selector switches, visual and audio indicators, relays, contactors, and voltage displays offer students hands-on, practical experience with equipment they might encounter in the field. The system also allows elevator process monitoring and control from anywhere using mobile devices and applications. TECHNICAL SPECIFICATIONS The PLC has 20 digital inputs, 12 digital outputs, 4 analog inputs, 2 analog outputs, and Ethernet communication. The system includes 8 toggle switches, 5 push-to-ON switches, 1 proximity sensor, 1 selector switch, 4 visual indicators, 1 audio indicator, 1 DC motor, 1 relay card containing 2 relays, 1 contactor, 4 inductive floor level sensors, 2 inductive limit sensors, 4 call-to-floor buttons with LED indicators, 4 bring-to-floor buttons with LED indicators, 5 seven-segment floor level displays, DC motor with reducer, transparent cabin door, and 1 IIOT device. EXPERIMENTS Program operation of NO (normally open) and NC (normally closed) instructions, types of logic gates, set and reset bit, types of timers, types of counters, types of compare instructions, types of math functions, MOV instruction, a..

PLC Control Traffic Light Control application Training System

FEATURES The PLC (Allen-Bradley/Siemens) system is equipped with 16 digital inputs and 16 digital outputs, providing the necessary I/O capabilities for various industrial automation tasks. It also features Ethernet communication support, enabling seamless integration into industrial networks for control and diagnostics. The system comes with PLC programming software, allowing users to program the PLC using standard languages such as ladder logic or structured text. The training system is an educational tool used for teaching students and engineers about traffic light control systems, automation, and PLC programming. This system simulates how real-world traffic light systems function, helping learners understand the interactions between inputs (timers) and outputs (such as traffic lights) controlled by a Programmable Logic Controller (PLC). Real-world components like proximity sensors, selector switches, visual and audio indicators, DC motors, relays, contactors, and voltage displays offer students hands-on, practical experience with equipment they might encounter in the field. TECHNICAL SPECIFICATIONS The PLC has 16 digital inputs, 16 digital outputs, and Ethernet communication facility. The system includes 8 toggle switches, 5 push-to-ON switches, 1 proximity sensor, 1 selector switch, 4 visual indicators, 1 audio indicator, 1 DC motor, 1 relay card containing 2 relays, 1 contactor, and 1 traffic light module. EXPERIMENTS Program operation of NO (normally open) and NC (normally closed) instructions, types of logic gates, set and reset bit, timers, counters, types of compare instructions, and types of math functions. Study of traffic lights. Study and use of memory bits and timers. Traffic light control by PLC through ladder programming. Study of signal indications for two directions. Students will gain practical experience with controlling multiple devices (LEDs, sensors, actuators) in a coordinated manner. Students will understand how timers and cou..

IIOT enabled PLC Control Temperature Control application training system

FEATURES The PLC (Allen-Bradley/Siemens) system is equipped with 6 digital inputs, 6 digital outputs, 2 analog inputs, and 1 analog output, providing the necessary I/O capabilities for various industrial automation tasks. It also features Ethernet communication support, enabling seamless integration into industrial networks for remote monitoring, control, and diagnostics. The system comes with PLC programming software, allowing users to program the PLC using standard languages such as ladder logic or structured text. Real-world components like temperature sensors, small heaters and fans, toggle switches, proximity sensors, selector switches, visual and audio indicators, DC motors, relays, contactors, and voltage displays offer students hands-on, practical experience with equipment they might encounter in the field. The system allows temperature control process monitoring and control from anywhere using mobile devices and applications. TECHNICAL SPECIFICATIONS The PLC has 6 digital inputs, 6 digital outputs, 2 analog inputs, 1 analog output, and Ethernet communication. The system includes 8 toggle switches, 5 push-to-ON switches, 1 proximity sensor, 1 selector switch, 4 visual indicators, 1 audio indicator, 1 DC motor, 1 relay card containing 2 relays, 1 contactor, 1 temperature sensor, 12V DC heater and fan with 6A relay, and 1 IIOT device. EXPERIMENTS Program operation of NO (normally open) and NC (normally closed) instructions, types of logic gates, set and reset bit, timers, counters, types of compare instructions, types of math functions, MOV instruction, analog inputs, and analog outputs. Interfacing of the temperature sensor with the PLC. Controlling a heater and fan for temperature control using the PLC through ladder programming. Learning how to develop and utilize cloud-based SCADA systems for global access to process data and remote control. With cloud SCADA, users can access live process data, control operations, and monitor systems from an..

IIOT enabled PLC Control Bottle Filling Application PLC Training System

FEATURES The PLC (Allen-Bradley/Siemens) system is equipped with 16 digital inputs, 16 digital outputs, 5 analog inputs, and 2 analog outputs, providing the necessary I/O capabilities for various industrial automation tasks. It also features Ethernet communication support, enabling seamless integration into industrial networks for remote monitoring, control, and diagnostics. The system comes with licensed PLC programming software, allowing users to program the PLC using standard languages such as ladder logic or structured text. Real-world components like toggle switches, proximity sensors, selector switches, visual and audio indicators, DC motors, relays, contactors, and voltage displays offer students hands-on, practical experience with equipment they might encounter in the field. The system includes a conveyor system with PLC control for the movement of bottles, including liquid filling operations and bottle counting, which is commonly used in bottling plants for packaging and distribution. The system also allows bottle filling process monitoring and control from anywhere using mobile devices and applications. TECHNICAL SPECIFICATIONS The PLC has 16 digital inputs, 16 digital outputs, 5 analog inputs, 2 analog outputs, Ethernet communication facility, and suitable licensed software. The system includes 8 toggle switches, 5 push-to-ON switches, 1 proximity sensor, 1 selector switch, 4 visual indicators, 1 audio indicator, 1 DC motor, 1 relay card containing 2 relays, 1 contactor, a conveyor system with motor unit, water pump, float switch, and solenoid valve. EXPERIMENTS Program operation of NO (normally open) and NC (normally closed) instructions, types of logic gates, set and reset bit, types of timers, types of counters, types of compare instructions, types of math functions, MOV instruction, analog inputs and outputs, and study of the bottle filling system. Interfacing of solenoid valves, pump, conveyor system, and capacitive sensor with the PLC..

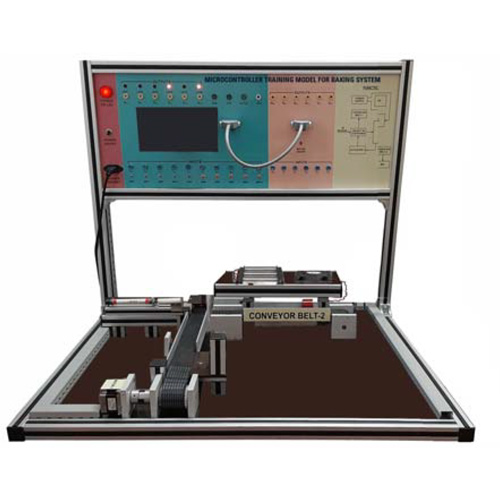

PLC and HMI Control Baking System application training system

FEATURES The PLC (Allen-Bradley/Siemens) system is equipped with 20 digital inputs, 12 digital outputs, 4 analog inputs, and 2 analog outputs, providing the necessary I/O capabilities for various industrial automation tasks. It also features Ethernet communication support, enabling seamless integration into industrial networks for remote monitoring, control, and diagnostics. The system comes with licensed PLC programming software, allowing users to program the PLC using standard languages such as ladder logic or structured text. The system includes a 7-inch HMI with Ethernet communication and programming software. Real-world components like toggle switches, proximity sensors, selector switches, visual and audio indicators, DC motors, relays, contactors, a baking system, solenoid valve, and BO motor offer students hands-on, practical experience with equipment they might encounter in the field. The system helps in understanding the concept of a baking system. TECHNICAL SPECIFICATIONS The system includes 8 toggle switches, 5 push-to-ON switches, 1 proximity sensor, 1 selector switch, 4 visual indicators, 1 audio indicator, 1 DC motor, 1 relay card containing 2 relays, 1 contactor, a conveyor system, BO motor, solenoid valve, heater, and exhaust fan. The Human Machine Interface (HMI) features a 32-bit 400MHz RISC CPU with a 7-inch high-resolution TFT LCD display (800 × 480) offering 65,536 colors. It supports a +24V DC power supply, has 128MB flash storage, 64MB DDRAM, and a high-precision four-wire resistive touchscreen, and includes an Ethernet interface for connectivity. EXPERIMENTS Program operation of NO (normally open) and NC (normally closed) instructions, types of logic gates, set and reset bits, types of timers (TON, TOFF, and TONR), types of counters (CTU, CTD), types of compare instructions (greater than, equal to, and less than), types of math instructions (addition, subtraction, multiplication, and division), analog input, and analog ou..

Industrial Sensor Training System

FEATURES The platform includes a wide variety of common industrial sensors, representing different sensing principles such as photoelectric, capacitive, inductive, and fiber optic, and configurations including through-beam, retro-reflective, and diffuse. Features like the protective enclosure, clear electrical terminals, and ease of operation suggest a user-friendly design suitable for beginners. The ready assignment details are particularly helpful for structured learning. The inclusion of a motorized module with speed control allows users to test the sensors in a dynamic environment, simulating real-world industrial applications. This is important for understanding sensor response in a control loop. The platform includes necessary components such as a power supply, counter, tachometer, and relay, making it self-contained and minimizing the need for external equipment. TECHNICAL SPECIFICATIONS The Photoelectric Through Beam Sensor features a through-beam sensing method, offering a maximum sensing distance of 5 meters, with a PNP control output and an operating voltage range of 12–24V DC, making it ideal for long-range object detection in industrial applications. The Photoelectric Retro-Reflective Sensor with a reflective sensor offers a maximum sensing distance of 2 meters, PNP control output, and an operating voltage range of 10–30V DC. The M6 Reflective Fiber coupled with a fiber sensor amplifier provides a PNP control output and operates within a 12–24V DC voltage range. The Diffuse Reflective Sensor offers a maximum sensing distance of 50–70 cm, PNP control output, and an operating voltage range of 10–30V DC. The Diffuse Reflective Sensor with adjustable sensitivity provides a maximum sensing distance of 10–30 cm, PNP control output, and an operating voltage range of 10–30V DC. The Distance Settable Sensor offers a maximum sensing distance of 2 mm to 80 mm, PNP control output, and an operating voltage range of ..

IIOT enabled PLC Controlled Water Level Control Application Training System

FEATURES The PLC system (Allen-Bradley/Siemens) is equipped with 8 digital inputs and 4 digital outputs, providing the necessary I/O capabilities for various industrial automation tasks. It also features Ethernet communication support, enabling seamless integration into industrial networks for remote monitoring, control, and diagnostics. The system comes with PLC programming software, allowing users to program the PLC using standard languages such as ladder logic or structured text. The system allows for remote monitoring and control via mobile devices and applications, enabling real-time process oversight from anywhere. A durable polycarbonate tank with a capacity to store water is designed specifically for accurate measurement purposes. The system is equipped with three float level switches to sense the low, middle, and high water levels in both the sump tank and measuring tank, ensuring precise monitoring of water levels. Visual indicators clearly signal when the process begins and ends, providing immediate feedback to the operator. A student-friendly software interface allows users to develop different programs, enhancing the learning experience and facilitating hands-on programming practice. TECHNICAL SPECIFICATIONS The system includes a PLC (Allen-Bradley/Siemens) with 8 digital inputs and 6 digital outputs (relay), with a program size of 4096 words. Ethernet interfacing enables smooth communication with external devices. The measuring water tank and sump water tank are made of polycarbonate and each measures 300 mm x 350 mm x 300 mm. Six float switches are included, with three in the upper tank and three in the lower tank, ensuring effective water level monitoring and control. The control panel features a metal frame enclosure, push buttons, indicators, and a buzzer for operation control. The control box includes MCB (16A), RCCB, and a 24V DC power supply (10A) for safe system functioning. The system operates on a 230VAC supply. The structure is buil..

Conveyor Belt Training System

FEATURES This conveyor belt training system provides basic training in the fields of automation technology and mechatronics. The setup is a modular and ergonomic learning system, allowing learners to acquire essential skills in mechanical assembling, commissioning, electrical commissioning, as well as sensor and control technology. The system can be dismantled and reassembled at a micro level to enhance skills in mechanical assembling, commissioning, and electrical wiring. The learning system is suitable for use in both single workpiece flow and goods carrier flow with pallets in the future. The system consists of at least one each of the following items: conveyor belt, DC motor, control box with control console, diffuse reflection sensor, through-beam sensor, 24V DC power supply, electrical cable set, and workpiece set. TECHNICAL DATA The operating voltage is 24V DC, 4A, with 100 W output power. The system includes 2 sensors for object detection. It has 8 digital inputs, 8 digital outputs, 2 analog inputs, and 1 analog output. Electrical connections use 4 mm banana sockets, with digital input/output signals in black sockets, analog input/output signals in white sockets, and 24V/0V in red and blue sockets. The conveyor belt training system dimensions are approximately 700 mm x 350 mm x 200 mm. The conveyor can be connected with the PLC system. CONVEYOR MOTOR SETUP The conveyor motor setup includes a DC motor, DC driver, and belt. The DC motor is mounted on a universal flange, allowing it to be easily replaced and converted. CONTROL PANEL The control panel includes a start button (N/O contact type, momentary, illuminated), a stop button (N/C contact type, momentary), a selector switch (N/C contact type, toggle), a reset button (N/O contact type, momentary, illuminated), and 2 indicator lamps. ELECTRICAL CABLE SET The cables include 4 mm banana cables with plugs that have a rigid protective sleeve and axial socket. The conductor cross-sectio..

IIOT enabled AC induction motor speed control training system using PLC and HMI

FEATURES The PLC (Allen-Bradley/Siemens) system is equipped with 12 digital inputs, 8 digital outputs, 4 analog inputs, and 2 analog outputs, providing the necessary I/O capabilities for various industrial automation tasks. It also features Ethernet communication support, enabling seamless integration into industrial networks for remote monitoring, control, and diagnostics. The system comes with PLC programming software, allowing users to program the PLC using standard languages such as ladder logic or structured text. The system includes a 7-inch HMI with Ethernet communication and programming software. Real-world components like toggle switches, proximity sensors, selector switches, visual and audio indicators, DC motors, relays, contactors, AC drive, and induction motor offer students hands-on, practical experience with equipment they might encounter in the field. The system allows AC motor speed control process monitoring and control from anywhere using mobile devices and applications. TECHNICAL SPECIFICATIONS The system includes 8 toggle switches, 5 push-to-ON switches, 1 proximity sensor, 1 selector switch, 4 visual indicators, 1 audio indicator, 1 DC motor, 1 relay card containing 2 relays, 1 contactor, 1 AC induction motor with VFD, and 1 IIOT device. EXPERIMENTS Program operation of NO (normally open) and NC (normally closed) instructions, types of logic gates, set and reset bits, timers, counters, types of compare instructions (greater than, equal to, and less than), types of math instructions (addition, subtraction, multiplication, and division), analog input, and analog output instructions using MOV instruction. Writing a ladder program to control an AC induction motor using the PLC. Creating a GUI in HMI to display the status of NO and NC contacts and control them. Creating a GUI to monitor and control timers in HMI. Creating a GUI to monitor and control a counter connected to the HMI. Creating a GUI to display and monitor analog input da..